Homepage > Sales > Building special > Facing brickwork

Facing brickwork

The planning and implementation of modern facing façades requires technical precision, experience and an approach to the facing brickwork that is tailored to the respective building project. We support clients, architects and contractors right from the early project phase with practical advice, thus creating the basis for a safe, economical and durable construction.

Thanks to our many years of expertise, we combine sound technical knowledge with a deep understanding of construction processes. If required, our consultants will come directly to your construction site or office to develop a code-compliant and practicable solution on site – from the base to the parapet. Often, even small adjustments to the building shell can simplify subsequent support and resolve particular design challenges at an early stage.

Working closely with experienced specialists, we develop all the necessary steps for a resilient and standard-compliant façade solution based on your planning documents – such as floor plans, elevations or details. This includes analyzing the structural conditions, taking expansion joints, interception planes and fixing points into account and selecting suitable systems for different load cases and installation situations.

It always starts with professional planning and structural analysis.

Based on the elevations, floor plans and sections/details, we work closely with three different structural engineering offices over many years to create a (verifiable) structural analysis and a concept for supporting the cladding façade.

These include:

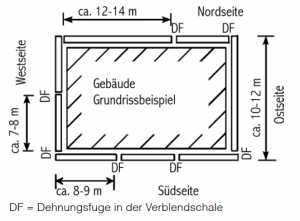

- Planning the horizontal expansion joints and, if necessary, the vertical expansion joints due to interception planes (intermediate interceptions, e.g. due to the height of the building). The wishes/requirements of the architect or building owner are taken into account, insofar as these can be implemented in accordance with standards.

- General drawings for each support structure, i.e. for each individual bracket position drawing, type designation and, if applicable, external dimensions of the bracket anchors or anchors, position and type of anchor channels or anchors including load determination, with details relevant for installation (e.g. edge distances of the fastening).

- Position plans created on the basis of the building elevations. The position numbers of the brackets, the interception levels, the expansion joints and, if necessary, information on the installation of the brackets are entered in these plans.

Preparation of a static calculation:

simple planning, not auditable:

For smaller/simple construction projects without a structural engineer, the general drawings and position plans in digital form are usually sufficient.

Complete façade statics, verifiable:

An external structural engineer is always involved for public buildings or larger properties. In this case, we prepare a complete, verifiable structural analysis for the cladding façade.

Planning the veneer support

Standards and regulationsn The planning and design of our brickwork support brackets naturally always comply with current standards and regulations, e.g. the fixing of brickwork is subject to the applicable building regulations. In accordance with the following standards, the support brackets are made of material grade W1.4571/1.4401(A4).- DIN 1045 Concrete and reinforced concrete, design and execution

- DIN 1053 Masonry; calculation and execution

- DIN 1055 Load assumptions for buildings

- DIN 18800 T7 Manufacture, suitability certificates for welding

- DIN 17440/DIN EN 10088-2 Stainless steels

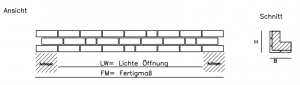

Suggestion for joint design:

Connected wall sections should not be wider than 7 to 14 m, depending on the geographical location. They are separated by vertical expansion joints.

- The minimum thickness of the outer shell is 90 mm. Thinner outer shells are regarded as cladding, the design of which is regulated in DIN 18515.

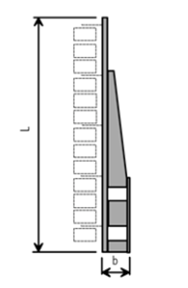

- Outer shells of 115 mm thickness (e.g. standard brick format NF or DF) should be supported at height intervals of approx. 12 m. A 115 mm thick outer shell may protrude up to a third of its thickness beyond its support (e.g. in the case of relief formation in the façade due to protruding or recessed stones) if the façade is not higher than 2 storeys or is supported every 2 storeys.

- Outer shells less than 115 mm thick (e.g. Danish standard format, WDF etc.) may not be installed higher than 20 m above ground level and must be supported at height intervals of approx. 6 m. These outer shells may protrude a maximum of 15 mm above their support.

- Masonry shells must be connected using wire anchors made of stainless steel with material numbers 1.4401 or 1.4571 in accordance with DIN 17440; the minimum number per m² of wall area is specified here, depending on the wind load zone, building height and anchor type

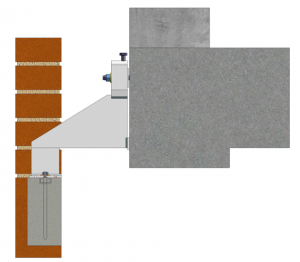

We supply individual brackets for a wide range of load cases and installation situations to suit the planned project. The brackets are manufactured in three load levels: 3.5 KN, 7.0 KN and 10.5 KN. All brackets can be adjusted in height by +/- 30 mm using a set screw in the loop head of the bracket.

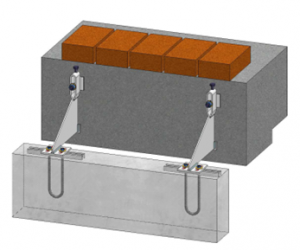

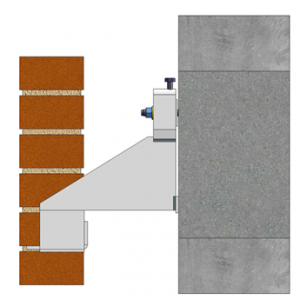

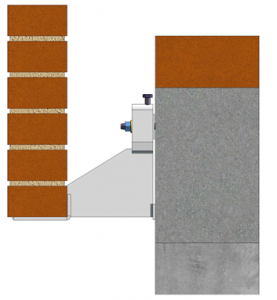

Supporting precast elements (facing lintels / precast concrete elements)

Support of precast brick elements with concrete core depending on static requirements. Suspension is by means of individual brackets. The prefabricated concrete lintel is bolted to the existing slotted holes in the support slab. The precast element has no lateral support (e.g. for lateral expansion joints), but can also be planned to be interlocked with the masonry. Your advantage: The brackets are matched to our prefabricated facing lintels and we are happy to provide our type statics for the prefabricated parts. The system of individual brackets and prefabricated part enables invisible support over façade openings.

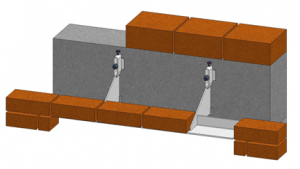

Interception of closed wall surfaces

Closed wall surfaces (e.g. for intermediate or base point supports) are usually supported with wrap-around brackets. These consist of one or more bracket backs, which are provided with brackets as supports for the masonry. They can also be used as a secure support over façade openings.

Special cases and special installation situations

For complicated cases, e.g. with challenging building geometry, at building corners, etc., we plan a “sustainable” solution in cooperation with you, the architect and/or structural engineer, otherwise we can produce a suitable bracket for practically any support situation, e.g:- Windposts for perforated masonry or parapet facing anchors if the parapet does not provide a suitable fixing base.

- Bottom view of veneer with anchoring in a concrete ceiling from below.

- Support on a wooden substructure

Of course, we always provide you with the right accessories and fasteners for the brackets, such as adhesive cartridges, hammerhead bolts, bolt anchors or screw-in adapters for mounting anchor rods.

Prefabricated veneer support

In addition to bracing and planning, we also offer prefabricated facing elements. These always match the selected brackets and thus form a static system. Your advantage: you only have one contact person for planning, brackets and prefabricated facing parts. Thanks to our many years of experience, we can not only offer standard lintels as stretcher or grenadier in all common stone formats, but also special prefabricated parts for a wide variety of façade designs, such as angled lintels, prefabricated parts for round or semi-circular windows, lower façade elevations or wall heads.

We have built particularly delicate precast elements such as pilaster strips with a cross-section of just 11.5 x 11.5 cm as well as very large precast elements such as balustrade panels over 165 cm high and 300 cm long, all with the necessary bracing!

In addition, we also offer you the usual special building articles for creating a facing façade, e.g.

- Air layer anchorWhether dowel anchors for subsequent drilling, flat anchors for mortaring into the rear masonry or anchors for timber and aerated concrete walls, for shell spacings of up to 400 mm.

- Z-foil / EPDM lintel foil

- We offer complete systems with foil, primer and adhesive for base sealing, lintel sealing and as a masonry barrier.

- Support spindles

- For easy support of prefabricated veneer parts during installation.

BV Town Hall Kaltenkirchen / 2022

Scope of services:

- Creation of the veneering statics

- Delivery of the interception, approx. 200 running meters of facing lintels

BV Siek fire department / 2020

Scope of services:

- Creation of the veneering statics

- Delivery of the interception and approx. 42 running meters