Homepage > Rental > Plastering and conveying technology > Mixing and Pumping

Mixing and Pumping

Conveyor pumps process machine-compatible premixed pasty masses such as coating materials, fillers, colourants, adhesives as well as ready-mixed construction site mortars.

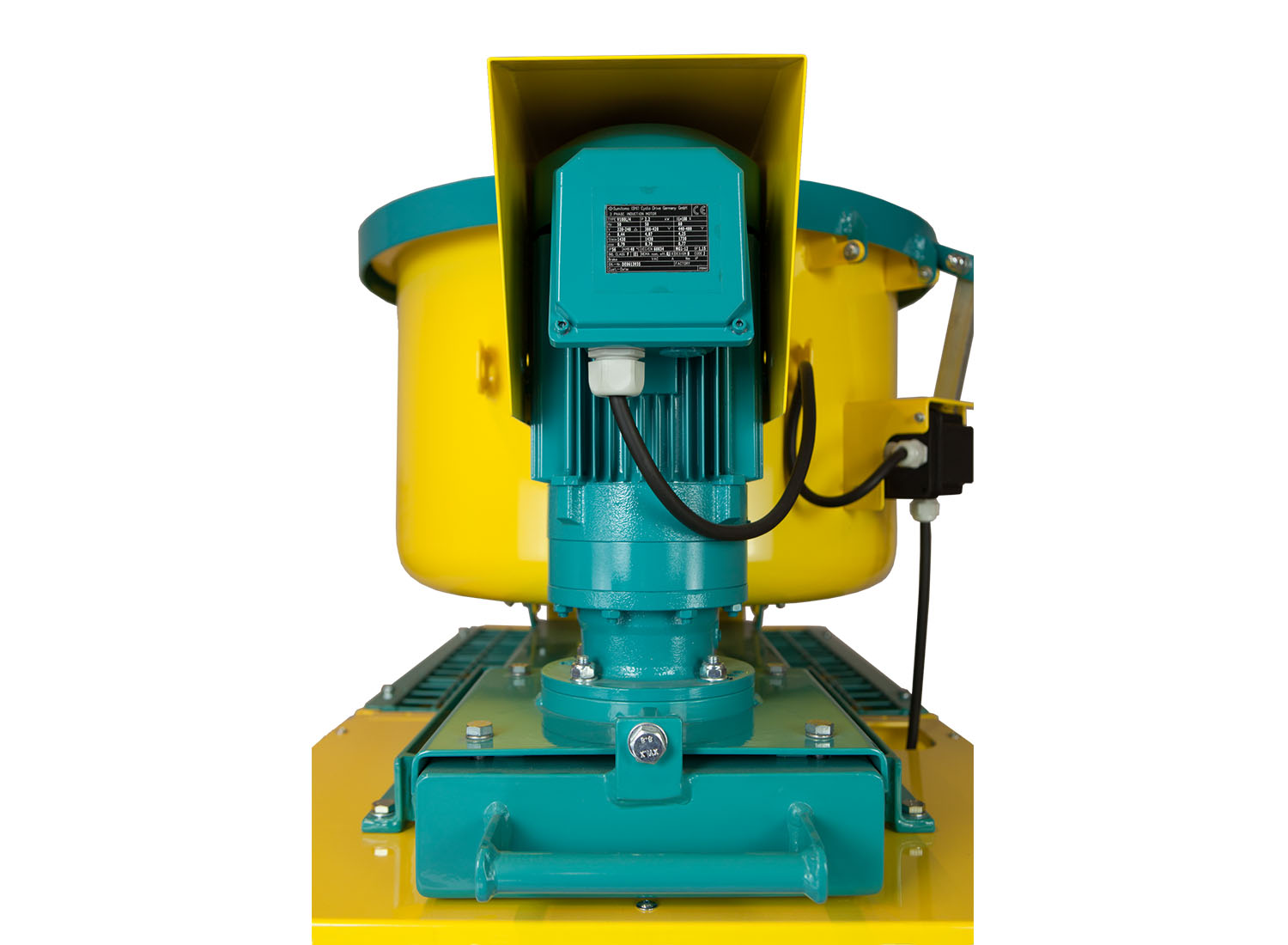

CONVEYOR PUMP >stockbig® No.3 Mixer / FU

- High delivery rate and delivery range

- wear-free, stepless regulation of the delivery rate via frequency converter (FU) optional

- can also be used as a mortar spraying or plastering machine with mixer and air compressor

- Robust and powerful

- controllable via remote control or air control

- low filling height

- Made in GERMANY

Optional accessories:

- Frequency-controlled motor for stepless control of the flow rate

Technical data:

Delivery rate:

according to pump type (7-40 l/min)

delivery distance:

max. 60 m

Drive:

Gear motor 7.5 kW / 400V

Forced mixer:

Gear motor 2.2 kW / 400V / approx. 56 rpm

Connection:

400V / 5 x 32A

Machine control:

via integrated pressure switch or remote control cable (42V)

Fuse protection:

3 x 25A slow-blow

Operating pressure:

max. 40 bar

Dimensions L x W x H:

approx. 2090 mm x 680 mm x 690 mm

Filling height:

615 mm

Hopper capacity:

approx. 125 litres (approx. 3 bags á 30kg)

Weight:

approx. 385 kg

The "all-in-one" CONVEYOR PUMP >stockbig® No.3 Mixer plus / FU

The universal delivery pump with powerful, frequency-controlled 7.5 kW / 400V drive (gear motor) for infinitely variable control of the delivery rate No.3 – MIXERplus is an “all-in-one” all-rounder. Suitable for ready-mixed dry mortar, wet mortar as well as machine-compatible proprietary mixes, pasty and liquid materials of all kinds. Expanded with an air compressor and spraying equipment, the >stockbig® No.3-400 delivery pump becomes a mortar spraying machine or plastering machine. Equipped with the optional drum mixer, the >stockbig® No.3 delivery pump becomes a powerful mixing pump for best mixing quality. Extended with air compressor and spraying equipment, the >stockbig® No.3 – MIXERplus additionally becomes a plastering machine. The built-in vibrating sieve holds back material that is too coarse-grained simply and safely. Available in mesh sizes 3, 4 and 7. Quality down to the smallest detail.

- High delivery rate and delivery range

- wear-free, stepless regulation of the delivery rate via frequency converter (FU) optional

- can also be used as a mortar spraying or plastering machine with mixer and air compressor

- Robust and powerful

- controllable via electric remote control or air control

- low filling height

- Made in GERMANY

Equipment:

- with mounted drum mixer, mixing capacity approx. 160 l

- gear motor 7,5 kW

- Large puncture-proof polyurethane wheels

- Mortar pressure gauge as safety equipment

- Service tool

- Operating instructions

- Frequency converter FU for stepless control of the delivery rate

Optional accessories:

- Power cable with CEE plug 32A – 5 x 4 mm² (25 or 50 m length)

- Air compressor (Metzger or Köllmann)

- Mortar pressure hose 35 mm hydraulically connected

- Air hose ½ inch completely integrated

- Fine plastering device 35 mm

- Remote control cable with switch 25 or 50 m

Technical data:

Delivery rate:

according to pump type (7-40 l/min)

delivery distance:

max. 60 m

Drive:

Gear motor 7.5 kW / 400V

Drum mixer:

Gear motor 0.5 kW / 230V

Mixed material quantity:

approx. 160 l

Connection:

400V / 5 x 32A

Machine control:

via integrated pressure switch or remote control cable (42V)

Fuse protection:

3 x 25A slow-blow

Operating pressure:

max. 40 bar

Dimensions L x W x H:

approx. 2090 mm x 680 mm x 1600 mm

Filling height:

615 mm

Hopper capacity:

approx. 110 litres (approx. 3 bags á 30kg)

Drum:

approx. 165 l

Weight:

approx. 387 kg